The injection technology applied in manufacturing polymer articles is a super clever production system to bring high consistency and productivity. As polymer being injected and shaped in the mold component, the whole process is automatic with digital program and robotic power, and production is efficiently and accurately repeatable. But meanwhile, everything is based on very skillful manual power to develop intricate formula and program systems. Calculation should involve prediction of material shrinkage, viscosity, flowability, leading to corresponding injection time, temperature, pressures – all demand rigorous manipulation from expert experiences and know-how.

PRODUCTION FACILITIES AND CAPACITIES

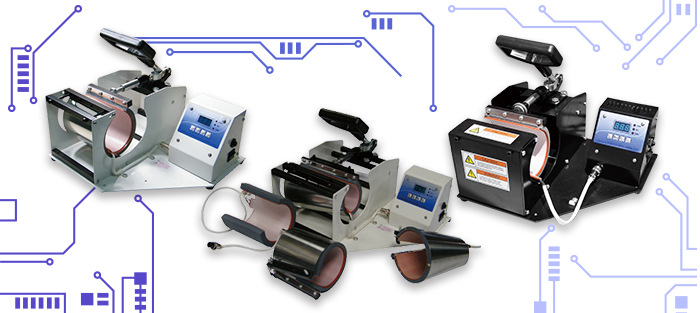

Started from 2004, we are among the first to manufacture sublimatable polymer blanks in China. The polymer injection factory is set in Guangzhou, a business and manufacturing hub, and the very same city our headquarter locate. With decades of experiences and accumulation, we develop the plant into a highly established line, gathered abundant machine capitals with our high-speed injection line, and an expert working team of engineering, programming, and machine operating. It’s a sturdy base supporting SUNPOLYTM to give stable, competitive, and always-up-to-standard supplies.

AUTOMATIC OPERATION

Equipped with advanced injection system and facilities, SUNPOLY™ factory provides quality and quick in-time polymer blank molding. We've got heavy robot-arm to move around molds, and the one-step polymer injection machines that automatically complete the whole operation from injection, molding, product demolding, and out-put belt convey. The process is highly productive and labor-saving, and at the same time reliable with low defect rate.